There are lots of workshop craft-based adages out there, from ‘skiving off’ (sitting down to work leather)and ‘show me your mettle’ (the pock marked hands of mill-stone dressers, proving to the miller that the journeymen were experienced in their trade). There is one, not quite so romantic, Plankbridge workshop adage that comes to mind: ‘If you’ve not done it before it takes twice as long.’ This crops up often, as a seemingly small variation in familiar things very easily takes twice as long, which needs bearing in mind as we plan ahead.

Building a shepherd’s hut is no mean feat. Enjoyable, yes, and extremely rewarding once it’s finished. But I’m pretty sure it will take at least twice as long as you thought it would, and cost several times more than expected in materials too.

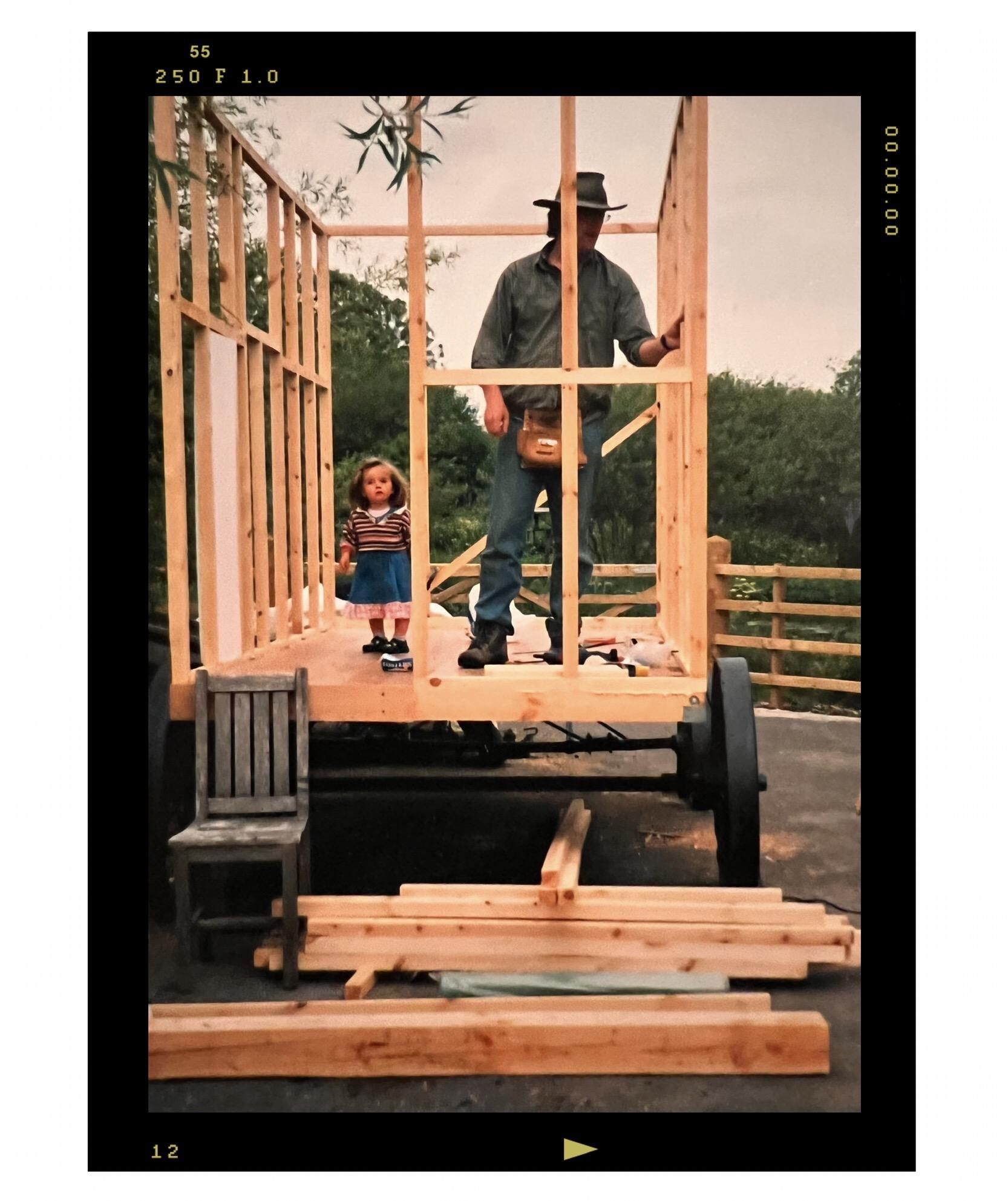

I remember the early days, when I would take a tape measure to old shepherd’s huts in the local area and make notes and sketches. There’s a photo of one of my first huts, about 20 years ago with daughter Hannah, and it shows the way I used to build the wall frames from locally milled Douglas fir. The floors were character grade solid oak and we stuck closely to the proportions of the originals. Still do, with our Snug model.

The shepherd’s huts that we built then were very much reproductions, with a simple ledge and brace door, and a small single glazed window. It’s a great project, and if old parts of bygone ironwork, gates, carts and even original shepherd’s huts can be worked in it makes for such a characterful end result. It’s making me want to get a restoration project underway again!

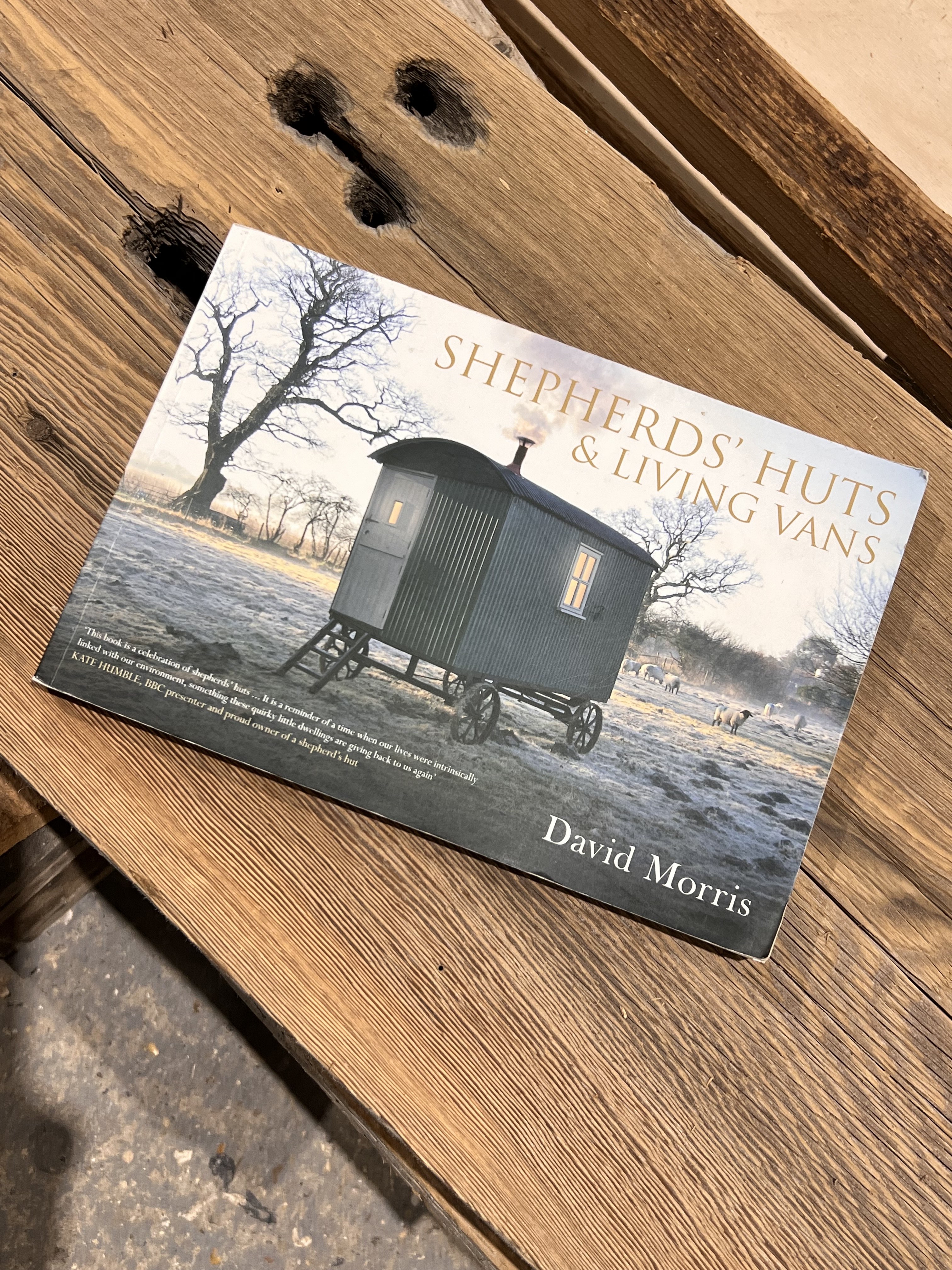

There are very useful books, such as Dave Morris’ Shepherd’s huts and Living vans’ that cover history and restoration. Several of our huts feature in the book, and I took the front cover photograph. It was on a delivery we did in the early days, leaving at midnight and arriving on the Suffolk coast before the customer was out of bed. The paddock, complete with her sheep, was just coming to life on a very cold, frosty morning!

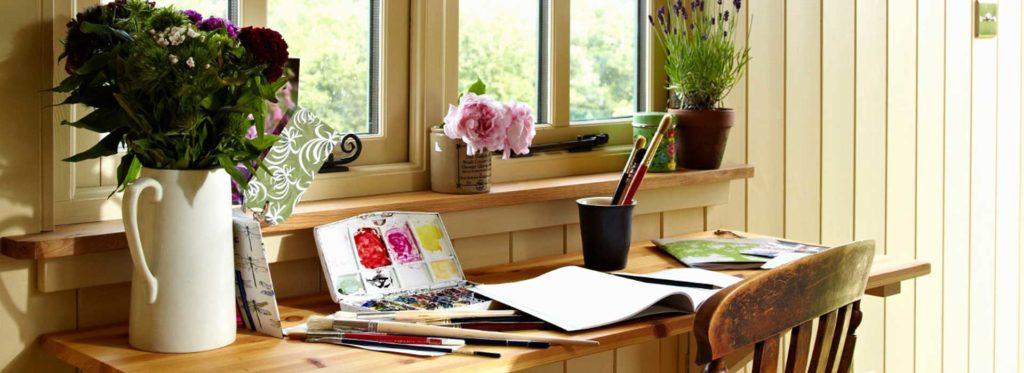

These days the builds are way more involved, often with a complex network of cabling and pipes, all fitted to standards which are signed off by registered plumbers and electricians. There are several details and build methods in the construction which need to be incorporated to make for a breathable and weathertight space for all year-round use. Get that bit wrong and it leads to trouble down the line.

Wise material selection, choosing the best quality is so important. Plankbridge huts use durable oak, V grooved panelling that has no knots that bleed resin and Thermafleece sheep’s wool insulation, all contributing to the best quality, long lasting build. The team have ‘honed their craft and carved their niche’, and this is such a valuable resource – I’m convinced there isn’t a more experienced bunch of shepherd’s hut craftspeople out there.

So, when gathering materials, don’t spoil the ship for a ha’porth of tar.

Or better still, if you are thinking of building a shepherd’s hut let us build it for you.