From screws and timber to the curved tin roof, every part of a Plankbridge hut first has to be sourced by our super-efficient Procurement Lead, Simon

What’s your back story and the journey that led you to Plankbridge?

I joined the Air Training Corps when I was 15, which meant I actually got to fly a plane before I could drive a car! Although the training is designed to lead into the Royal Air Force, I decided instead to join Europe’s leading photographic laboratory at the age of 18 where I progressed quickly and established my own finishing department, managing machinery and producing everything from small prints to huge displays.

After I met my future wife, an opportunity came up to move from Chandler’s Ford where we lived and join an exhibition company in Dorset, where I ran a large workshop, building exhibitions and working on projects for everything from local museums and the Farnborough Air Show to the NEC. Eventually, the business was sold, and five years ago I heard about a hutmaker vacancy at Plankbridge through my wife and never looked back. In early September I took up a new role as Procurement Lead.

Can you share with us what that entails?

Sourcing and managing all the parts, tools and materials for our huts – everything from the screws to the tin for the roofs. There are lots of moving parts to this role, but it is really satisfying knowing that everything is exactly where it needs to be and that we have good relationships with our suppliers. I’ve also enjoyed putting my own stamp on the role and setting up new systems to improve efficiency, re-organising some of the workspaces and introducing even more eco-friendly practices.

What do you most enjoy about your job?

Procurement is quite a demanding job, requiring a certain amount of quick thinking and creative solutions to keep things on track – navigating supply chain challenges and tight deadlines – but I love the challenge and get a lot of satisfaction out of making sure everything runs smoothly. I live in Piddlehinton, where the Plankbridge workshop is based, so it’s great to be able to get to work so quickly. I even built an electric bike so I could tackle the hill!

What do you like to do outside of work?

I love building radio-controlled model aircraft, an interest I inherited from my father. I’ve converted my garage into a workshop where I work on large-scale 4.5 metre wing span gliders – a hobby that requires knowledge of everything from materials, electronics to aerodynamics. I also enjoy walking and fishing. There are some fantastic places to fly-fish nearby, and I am a member of a local fishing club. Sometimes I’ll arrive at a stretch of water to find I have it completely to myself.

You source all the timber for our huts. Do you have a favourite for the interior?

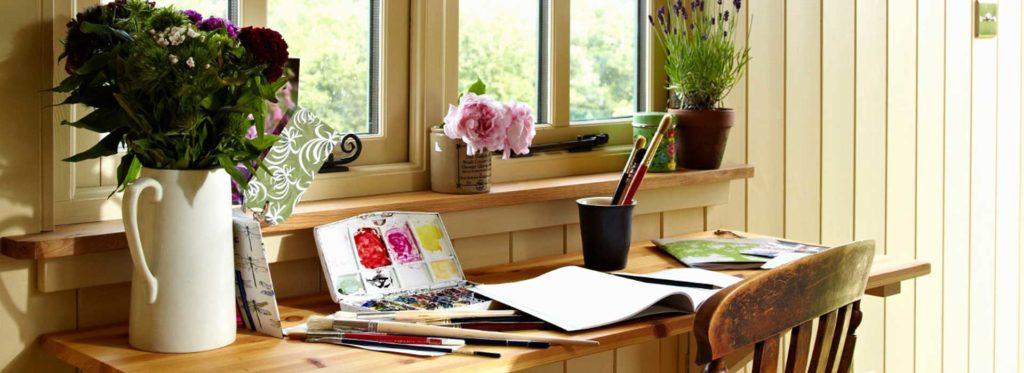

The Watermill; it’s beautifully rustic and looks so authentic. That’s what I love about Plankbridge – it’s the DNA. No other shepherd’s hut company has what we have: the early beginnings with the Prince’s Trust, the fact that we are the only hutmakers to be endorsed by the RHS. It’s the little things that set us apart from the competition.

Meet other members of our talented team, here